E. Skoplaki and A.G. Boudouvis of Greece have also conducted a series of related experimental studies on photovoltaic panels. The results indicate that the actual power generation of these panels primarily depends on the conversion efficiency between light energy and electrical energy. Based on the experimental results, they derived a working equation that primarily depends on temperature variations, including both the real-time ambient temperature and the panel’s own temperature, as well as local light intensity, wind force, and key performance indicators related to its design and installation. In response to these factors, scientists and engineers have developed products with self-cleaning functions. This new type of solar panel offers advanced intelligence in many aspects.

Malay K. Mazumder from Boston University, who led the research, also developed a design that enables photovoltaic panels to perform self-cleaning. This cleaning technology uses a portion of the photovoltaic panel’s electrical energy, causing slight vibrations that shake off accumulated dust, thereby completing the self-cleaning process. The original intention of the researchers was to solve the problem of cleaning photovoltaic cells on aerospace vehicles. A protective plate made of indium tin oxide electrode is attached to the photovoltaic cells, and its surface generates static waves. When an electric pulse flows through the electrode, it generates dielectrophoretic forces, which effectively shake dust particles, regardless of whether they are charged. This automatic cleaning technology, which uses vibrations to remove dust from the surface of photovoltaic panels, can eliminate 90% of the dust in a short time. Larger photovoltaic cells tend to accumulate more dust and impurities. Dust reduces the energy conversion efficiency of photovoltaic panels, particularly in desert areas where they are more susceptible to wind and sand. Therefore, the emergence of this dust-shaking technology has partially resolved the issue of reduced power generation efficiency in photovoltaic panels, particularly in specific areas.

The development and research of coatings have also been prioritized. Researchers have developed a coating that enables the panels to clean themselves. This coating not only cleans the surface but also slightly increases the panel's power output, thereby significantly reducing maintenance costs. By acting as an isolation layer between the panels and the environment, the coating prevents pollutants from easily contacting the panel surface, thus maintaining the solar energy conversion efficiency. In the long run, although using this coating increases the initial installation cost, it saves significant amounts in subsequent maintenance, making it highly practical.

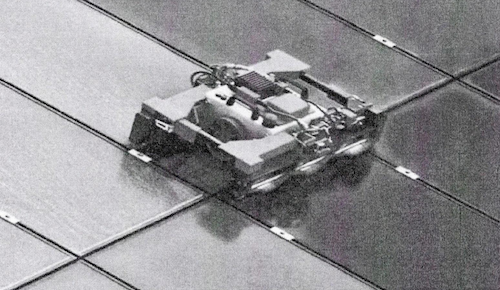

Relevant researchers stated, "This invention demonstrates that universities are not only committed to technical research in laboratories but are also extending their work to practical applications that generate economic benefits." Researchers at Tel Aviv University (TAU) have made a breakthrough in the development of nano-scale coatings. This nano-scale coating features a continuous structure that can also perform a self-cleaning function. Composed of polypeptide substances, this coating exhibits strong performance indicators in several areas. In Japan, researchers have designed an intelligent micro-robot primarily used in remote areas with limited water resources. It uses a rotating brush and can operate for approximately two hours on a single charge. While the cleaning efficiency of this robot is high, the associated costs also rise.

Figure 1-1 Photovoltaic panel cleaning micro-robot

Despite this, China has developed some theoretical concepts, but we have not made substantial progress in the actual cleaning process. Dust accumulation exhibits a degree of randomness and uncertainty. Dust accumulation in different states requires specific cleaning methods to meet the corresponding cleaning standards. Moreover, the accuracy of the measured data during the detection process is a critical parameter. It enables real-time, accurate, and efficient cleaning of dust accumulation to optimize light energy conversion. This is an area that requires further study. The cleaning system designed in this project primarily utilizes photovoltaic solar energy conversion. The solar panels and energy storage batteries form the mechanical structure of the cleaning bracket, which uses the photovoltaic effect to convert between the two energy sources. After conversion, the energy storage battery stores electrical energy, which is then used to power the load motor. When needed, the electrical energy is released to power the system. The cleaning component is controlled by a controller that manages the DC servo motor, which drives the roller brush to clean the solar panel. The goal of this project is to provide an automatic solar panel cleaning device that employs sensor-based technology, requires no manual operation, and significantly reduces labor. The cleaning process uses various sensors to collect data and control the timing, ensuring that the cleaning function operates automatically under low temperatures and minimal evaporation. It features water efficiency, good reliability, good resistance to interference, ease of use, and long-term stability, and offers significant environmental benefits.