The overall design goal of this project is to develop a system capable of intelligently cleaning outdoor photovoltaic panels. The system's power is generated by the photovoltaic panel itself. When the photoelectric sensor detects dirt on the solar panel's surface, the cleaning system automatically starts and stops to complete the cleaning process. Simultaneously, the pressure sensor monitors the nozzle pressure at the water spraying point to control the water flow. Especially in winter, when low outdoor temperatures cause ice to form on the solar panel's surface, the cleaning system includes a self-heating function to prevent damage to the photovoltaic components before operation begins.

To achieve the ideal cleaning control of

photovoltaic panels, it is crucial to address the following challenges:

The cleaning system designed in this project can detect and analyze the surface coverage of the photovoltaic substrate through photoelectric sensors, automatically starting and stopping the cleaning process. First, external environmental factors must be detected. This step primarily involves detecting light intensity. Next, by calculating and analyzing the light intensity change curve, it is possible to verify whether the reduction in solar photovoltaic conversion efficiency is due to dirt on the surface.

Since the cleaning device uses water to clean the photovoltaic panels, when the outside temperature drops below 0°C, water molecules tend to solidify. This not only hinders cleaning but may also reduce the components' service life. Therefore, when the temperature falls below 1°C in winter, the automatic heating function activates before the cleaning system starts. When the water spray device operates, the system's heating function is also activated. Once heated, the water can remove frost and other coverings from the photovoltaic panels.

The cleaning system in this project is powered by the photovoltaic panels themselves. This power usage depends on the electricity converted by the photovoltaic panels. This eliminates the need for additional energy facilities, making the system recyclable, clean, and environmentally friendly.

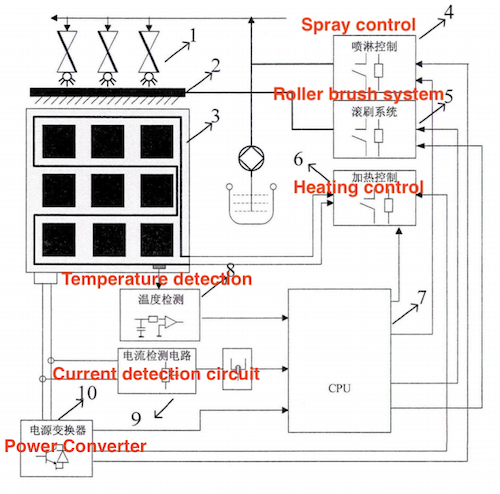

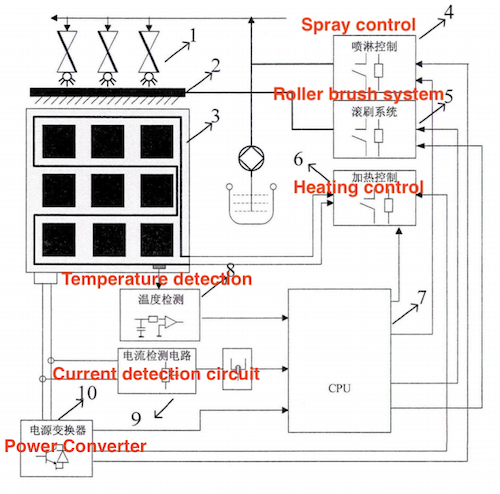

The cleaning control system studied in this project consists of two main components: electronic control and mechanical structure. The mechanical structure includes the support frame and brush frame of the photovoltaic panel, while the control structure consists of module units, including the controller, sensor detection unit, instruction transmission unit, motor control unit, and power adjustment unit. The system structure is illustrated in Figure 2-1.

Figure 2-1 Overall structure of the control system

In Figure 2-1, 1 represents the solenoid valve, 2 the roller brush, 3 the thermal resistor, 4 the spray subsystem, 5 the roller brush subsystem, 6 the temperature control system, 7 the controller, 8 the temperature sensor, 9 the current detection circuit, and 10 the power converter.

The operational steps of this system are as follows: the photovoltaic panel captures sunlight energy during normal operation, converts it through the photovoltaic effect, and then supplies the solar battery, which powers the control board. At this point, the system’s detection function activates, analyzing set data indicators such as dust accumulation on the solar panel to determine the specific operation steps and cleaning time. If cleaning is required, the motor activates to move the slider along a predetermined trajectory, enabling the sliding rod with the roller brush to perform a reciprocating motion on the photovoltaic panel, thereby removing pollutants and achieving the system’s automatic cleaning function. The system’s control structure is mainly divided into:

- System intelligent sensing module

- Control system

- Cleaning module

These three main components constitute the photovoltaic panel’s automatic cleaning control system. The intelligent sensing module detects and analyzes the surface covering of the photovoltaic cell substrate. After transmitting the data to the control system’s microcontroller for processing, the cleaning system is automatically controlled to start and stop.