This paper provides an overview of the current state of solar cells, focusing on the rapid global growth of photovoltaic modules and their role in renewable energy. It also analyzes the production process of crystalline silicon solar cells, their environmental impact, and the strategies for managing and recycling solar cell waste. As the world moves toward net-zero carbon emissions, the solar power industry is expected to continue growing. However, the industry faces significant environmental challenges, particularly regarding waste disposal and solar cell recycling. The paper concludes by reviewing current recycling technologies and waste management strategies, highlighting the need for further research and development in this field.

Since the industrial era, the use of fossil fuel has contributed to the greenhouse effect, resulting in energy shortages and environmental degradation. The transition to renewable energy is crucial in addressing these challenges. In recent decades, renewable energy sources such as wind, tidal, and biofuels have been explored. Among these, solar energy technology has advanced the most rapidly and boasts the highest global adoption rate. Solar energy is one of the most abundant, clean, and efficient energy sources worldwide. Solar power generation is safe, environmentally friendly, and produces no noise or pollution. By 2050, solar photovoltaic technology is expected to become a leading energy source, contributing 10% to 20% of global power generation, or more.

Over 50% of countries and regions worldwide have committed to "zero-carbon" goals, which is expected to accelerate photovoltaic power generation growth and expand the industry. The top three countries by installed capacity are China (32%), the United States (13%), and Japan (12%). Global solar power generation capacity increased from 135 GW in 2013 to 600 GW in 2019. By the end of 2022, global solar power generation is expected to reach 1,200 GW. By 2050, it is expected to reach 4,500 GW, contributing 13% of total power generation.

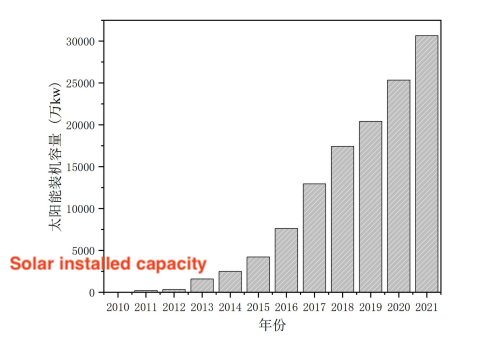

The photovoltaic industry's growth aligns with China’s goal of carbon neutrality. In recent years, solar cell technology has developed rapidly and holds significant market potential. China’s photovoltaic industry has expanded rapidly, positioning the country as the global leader in the sector. By 2019, China's cumulative installed capacity reached 204.18 GW, increasing to 253.43 GW by 2020, and 306.56 GW by 2021. Achieving carbon neutrality requires limiting fossil fuels to around 20% and ensuring renewable energy accounts for approximately 70%. Consequently, the solar power generation industry is expected to continue growing, playing a critical role in achieving the "carbon neutrality" goal.

Figure 1 China’s Photovoltaic Installed Capacity

Photovoltaic products have developed through four generations. Materials used to manufacture solar panels include silicon, cadmium telluride, cadmium sulfide, and copper indium selenide. Currently, first-generation (crystalline silicon technology) and second-generation (thin-film solar cells) technologies dominate the market. These solar cells offer advantages such as high efficiency, light weight, low production costs, and ease of manufacturing.

The third generation of solar cells, including nanocrystalline thin films based on II-V materials and dye-sensitized solar cells, utilizes novel but expensive materials, resulting in lower efficiency and shorter lifespans. Fourth-generation (inorganic-organic) solar cells are flexible films made from new inorganic metal nanoparticles/oxides and organic nanomaterials, including carbon nanotubes and their derivatives. These are currently under active research.

Crystalline silicon solar cells have been widely used since the early 1950s. Silicon is a non-toxic, abundant material that can be easily sourced. Over the past several decades, silicon wafers have demonstrated stability and high photoelectric conversion efficiency in practical applications. They currently account for 80-90% of the market.

The production of solar panels involves components such as aluminum, glass, and crystalline silicon, all of which require the use of chemicals and hazardous materials. During production, greenhouse gases, such as carbon dioxide and methane, are released, contributing to environmental degradation. High-purity silicon used in solar cells is derived from silicate minerals, primarily silicon dioxide ores. The manufacturing process involves the high-temperature reduction of silicon dioxide with carbon, followed by hydrochloric acid treatment, often using copper. This process generates silicon tetrachloride, a byproduct that is challenging to manage and contributes significantly to environmental pollution. Additionally, significant dust is produced during the cutting of solar cells. Chemicals such as hydrogen, hydrochloric acid, nitric acid, isopropanol, and ammonia are used during various stages, including separation, extraction, production, and cleaning. Many of these chemicals are flammable, corrosive, and toxic, posing significant risks to both human health and the environment.

Crystalline silicon solar cells typically last 25 to 30 years, and global solar panel waste is projected to reach 5.5 to 6 million tons over the next three decades. Historically, due to insufficient regulations, many solar cells have been disposed of in landfills alongside other waste. In 2014, the European Union amended the Waste Electrical and Electronic Equipment (WEEE) Regulation to include photovoltaic components, thereby integrating them into the electronic waste management system and mandating recycling to reduce landfill waste. This has led to increased material recovery from photovoltaic waste by recyclers in Europe. Similarly, China has increasingly focused on photovoltaic waste recycling. In 2021, national agencies introduced the "General Technical Requirements for Recycling and Reuse of Photovoltaic Modules." Since 2015, China has experienced a rapid increase in solar panel waste, with a significant surge anticipated by 2030. As a result, solar panel recycling and disposal will present a critical environmental and resource challenge in China over the next decade, necessitating continued research and development in this emerging field.

The disposal of solar photovoltaic waste in landfills can lead to the leaching of pollutants. Environmental events, such as hurricanes, hail, storms, and landslides, can cause the leachate from solar cells to create severe environmental risks. Studies indicate that polycrystalline silicon modules reach leaching equilibrium within one year when disposed of in landfills. The leaching concentrations for lead (Pb), copper (Cu), aluminum (Al), and nickel (Ni) are 0.29, 5.42, 3.68, and 1.104 mg/g, respectively. Research also indicates that the use of two layers of encapsulant bonding glass and backplane in crystalline silicon wafers increases the release of ethylene-vinyl acetate (EVA), potentially contributing to higher carbon emissions. Reports suggest that disposing of solar photovoltaic waste in urban domestic landfills can significantly increase pollution potential, with an estimated 5.15% increase in landfill pollution due to the introduction of photovoltaic waste.

Aged or damaged solar panels are typically sent to glass recycling plants for the recovery of recyclable glass materials. The process begins with cutting the edges of the aluminum frame, removing the remaining frame components, and separating the cables. The aluminum frames are collected, while the cables are sent to a separate facility for further processing. Plastic components from cable packaging and other residual materials are incinerated in cement kilns as part of the disposal process. Although incineration recovers some energy from the combustion of polymers, the process also releases harmful gases and generates toxic ash. Fly ash from incineration is disposed of in landfills according to environmental regulations, while metal bottom ash is typically recovered through methods such as screening, acid leaching, electrolysis, neutralization, and filtration. The treatment of bottom ash also generates significant quantities of waste acid, which is separated from sludge containing unrecovered metals through neutralization and filtration. These byproducts are sent to landfills for final disposal. As a result, the use of fossil fuels for transportation, incineration, fly ash treatment, and recovery processes contributes to significant environmental impacts.