Since China's photovoltaic power stations are mostly located in desert areas with a lot of sand, dust, and a harsh environment, the accumulation of dust, dirt, and other pollutants significantly reduces the power generation efficiency of solar panels. Therefore, cleaning the Photovoltaic cells becomes key to ensuring their long-term efficient operation. Traditional manual cleaning methods are not only time-consuming and laborious but may also damage the panels. To solve these problems, an automatic cleaning control system for solar modules was developed. This project designed an automatic cleaning control system for outdoor photovoltaic panels to clean the solar modules promptly, reduce environmental damage, improve energy utilization, and meet the water-saving requirements of photovoltaic power stations.

- Sensors play a pivotal role in the functioning of photovoltaic systems, serving as the 'eyes' that monitor environmental conditions and the integrity of solar panels. These devices are primarily used to detect dust, dirt, and other contaminants that can accumulate on the surface of photovoltaic cells. Among the various types of sensors used in this context, photoelectric sensors stand out for their ability to detect changes in light intensity caused by surface obstructions. By emitting a beam of light and measuring its reflection or interruption, these sensors provide immediate feedback on contamination levels. Ultrasonic sensors also contribute to this monitoring process by emitting sound waves and analyzing their reflections off surfaces. They are particularly effective in determining distances and can identify accumulations on solar panels without direct contact. Additionally, image sensors have emerged as vital tools for assessing panel cleanliness. These devices capture visual data that can be processed using image analysis algorithms to identify not only dirt but also larger debris that may hinder performance. This capability allows for a nuanced understanding of contamination patterns over time. The integration of these sensors enables real-time data acquisition, which is then transmitted to a central controller for analysis and decision-making. Thus, employing these sophisticated sensing technologies is crucial for maximizing the operational efficiency and longevity of photovoltaic systems.

- The controller is the 'brain' of the system, responsible for receiving data from the sensors and making appropriate decisions. Based on the preset cleaning threshold and contamination status, the controller can automatically determine whether cleaning operations are needed and control the actions of the actuator.

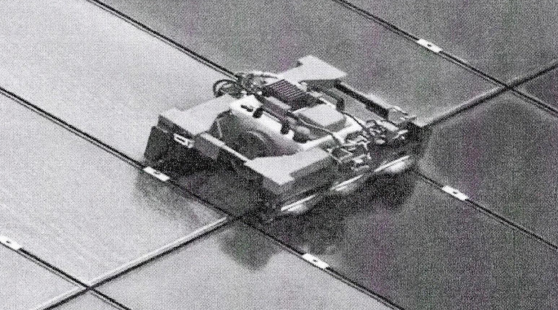

- The actuator serves as a critical component in various automated systems, functioning as the 'hand' that performs tasks assigned by the controller. This role is particularly evident in applications such as sprinklers, brushes, and wipers, where mechanical movement is essential for achieving specific objectives. In the context of cleaning solar panels, the actuator's function becomes paramount. It translates electronic signals from the controller into physical actions that ensure optimal maintenance and performance of solar energy systems.

- Pollution detection: The sensor monitors the contamination status on the surface of the solar cell in real time.

- Data transmission: The sensor transmits the detected data to the controller.

- Decision-making: The controller determines whether the cleaning threshold is reached based on the received data. If it is reached, the cleaning process begins.

- Cleaning execution: The controller controls the actuator to perform cleaning operations, completing steps such as water spraying, brushing, and wiping in sequence.

- Effect feedback: After cleaning is completed, the sensor detects the surface of solar cells again to ensure that the cleaning effect meets expectations.

- Improving power generation efficiency: The automatic cleaning system can promptly remove dust and dirt from the surface of solar panels to maintain their efficient power generation capacity.

- Saving labor costs: Compared with traditional manual cleaning methods, automatic cleaning systems can significantly reduce labor investment and operating costs.

- Extending equipment service life: The automatic cleaning system uses a gentle cleaning method to avoid possible damage caused by manual cleaning, thus extending the life of the solar panels.

- Improving security: In high-risk environments, such as high altitudes or remote areas, automatic cleaning systems can replace manual operations and reduce safety risks during the cleaning process.