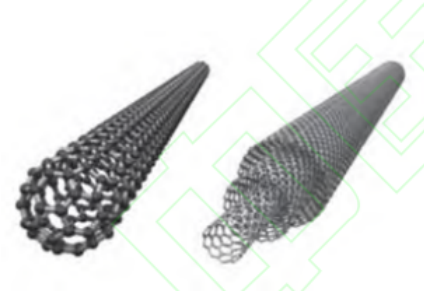

Figure 1 The structure of carbon nanotubes

Ti foil is used as a substrate to prepare a flexible perovskite solar cell with an efficiency of 8.31%. The opacity of Ti foil prevents light from entering the anode. Inspired by Li's work, Wang took advantage of the light transmittance of carbon nanotubes to make incident light pass through the carbon nanotube counter electrode to reach the perovskite light-absorbing layer. Then, The device was subsequently subjected to mechanical bending tests 100 times, and the performance remained basically unchanged, indicating that the carbon nanotubes have good flexibility for the counter electrode. Later, Li and other people used three materials such as single-walled carbon nanotubes (SWCNT), graphite and carbon black as the counter electrode. As a good conductor, the single-walled carbon nanotube is a good conductor to improve hole collection efficiency and extend the service life of carriers and obtain the highest photoelectric conversion efficiency of 14.7%. In 2016, Lin and others extracted cross-stacked carbon nanotube sheets (CSCNTs) from carbon nanotube arrays with excellent conductivity, porosity and flexibility, and used them as the counter electrode of PSCs hole free transport layers; iodine was mixed with CSCNTs to obtain the cell's highest efficiency of 10.54%.

In the following year, Yang and the rest of the team mixed boron with multi-walled carbon nanotubes, which made the work function of the carbon nanotube counter electrode more compatible with the perovskite and was more conducive to reducing the barrier of hole transmission from the perovskite layer to the counter electrode layer. The hole transport ability was improved, and the photoelectric conversion efficiency also increased from 10.7% to 14.6%. In 2017, Aitola and others compared carbon nanotubes and gold as counter electrodes. The initial efficiency of carbon-based cells was lower than that of metal electrodes. However, as the temperature increased, the cell efficiency of metal electrodes decreased significantly in a short time. After eight hours, 20% of efficiency lost, while the carbon-based cell lost only 0.04% of efficiency. This is because gold atoms move to the perovskite layer when the temperature is slightly high. Also, Carbon nanotubes are hydrophobic, which prevents the perovskite from contacting moisture and oxygen in the air. To make the interface contact between the carbon nanotube film and perovskite film denser, Kim and others prepared a simple cell with TiO, CH NH PbI or CNT structure. A thinner layer of carbon nanotube counter electrode was put on the Pbl2 layer by low-temperature scratch coating and CHGNHI solution was spin-coated, forming an interlaced interface of perovskite and carbon nanotubes, which chemically promoted close contact of the interface. An interlaced interface of perovskite and carbon nanotubes, which chemically promoted close contact of the interface.

In the same year, Yang and the rest of the team developed an ultrasonic spray method to deposit a multi-walled carbon nanotube counter electrode film with a thickness of 5 to 20 um. When the ultrasonic spray method was used to directly deposit carbon nanotubes on the perovskite film, contact without gaps could be formed on the perovskite or carbon interface. The formed carbon nanotube counter electrode was also more delicate; the carbon nanotubes were cross-linked with each other, and the conductivity and hole transport efficiency were greatly improved. Later, researchers became very interested in the combination of nanoparticles and carbon nanotubes counter electrodes. Lin and others used nickel oxide nanoparticles and single-walled carbon nanotubes to make composite carbon films. NiO is an inorganic p-type semiconductor with a deep valence band (VB), which greatly promotes hole extraction. Single-walled carbon nanotubes have good electrical conductivity, and the addition of NiO significantly improves the overall hole transport performance of the electrode, making the short-circuit current density Jsc as high as 20.70 mA/cm2. In 2018, Hu smoothly mixed CuS nanoparticles with the carbon nanotube counter electrode layer through a low-temperature method, and found that the addition of CuS particles greatly improved the hole extraction ability of carbon nanotubes. When 1wt% CuS nanoparticles were added, the electrode conduction effect was optimal, making the Voc as high as 0.98 v, and the efficiency reached 11.28%. Researchers used different methods to modify the carbon nanotube counter electrode due to the poor adhesion of carbon nanotube film.

Zhou and others prepared a new type of polyethyleneimine modified cross-laminated carbon nanotube (CSCNT) film as the counter electrode of the trans-structured cell. The mixing of an appropriate amount of PEI had a positive effect on the electrical properties and energy levels of the carbon nanotube film. Finally, a proper energy level matching was obtained, and its adhesion was improved, promoting the transferring of the interface charge, reducing the hysteresis effect, and significantly improving the photovoltaic performance of the cell. The following year, Raja and other people mixed the hybrid polyenediimide with CNTS to prepare a film with excellent conductivity, good thermal stability, and good adhesion. The unencapsulated device has excellent stability after being exposed to continuous sunlight. After six weeks of outdoor exposure, the battery only lost its initial 30% of efficiency. Chen and the team used oxygen-containing functional groups to modify carbon nanotubes and used them as electrode materials. The results showed that the treated counter electrode improved the recrystallization of the CH3NH3Pbi3/C interface and improved its hole extraction ability. The long-term storage efficiency can still be maintained at 9.54% to 12.14%. In 2020, Guo and others used carbon nanotubes and carbon nanofiber composite materials as the counter electrode of PSCs. The coordinated effect of carbon nanotubes and carbon nanofibers provided a fast path for hole transport. The efficiency of the cell has also been greatly improved, with an efficiency of up to 11.8%.

The one-dimensional structure of carbon nanotubes has the advantages of small sizes, good flexibility, and good conductivity. It is easy to form carbon electrodes with good connectivity, high mechanical strength and fast charge transfer. The excellent photoelectric properties make carbon nanotubes the most valuable carbon at present. Whether carbon nanotubes alone or in combination with other materials as the counter electrode material, it shows good device efficiency. Element mixing or functional modification is important for adjusting the work function and conductivity of carbon nanotubes.