Relevant researchers said that a new and simpler solution for manufacturing stable peroxide solar cells overcame the key bottleneck of the large-scale production and commercialization of this promising renewable energy technology, and this technology had been out of reach for more than a decade. The work of researchers now paved the way for the commercial production of low-cost, high-throughput large-scale solar modules in the near future.

Researchers were able to prove this method with two micro-modules, which reached the championship level of converting sunlight into electricity and greatly extended the working life. We believe this process can easily adapt to scalable manufacturing in an industrial environment due to its simplicity and low costs. For decades, peroxide photovoltaics have been regarded as a feasible competitor for silicon-based photovoltaics that is familiar in the market, which has been a highly anticipated emerging technology in the past ten years. The production of high-efficiency silicon peroxide solar cell modules expanded from the workbench to the factory has been hindered due to the lack of solutions to the grand challenges in this field.

The team worked in collaboration with researchers from National Taiwan University (NTU) and invented a one-step spin-coating method by introducing sulfane as an additive in the precursor of peroxide, or a liquid that generates peroxide crystals through a chemical reaction. The crystal is then deposited on the substrate just like other manufacturing methods.

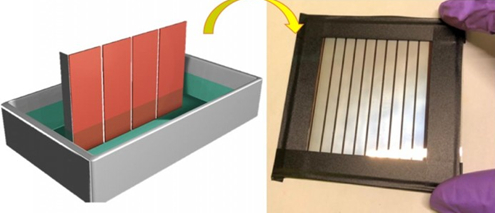

The new process enables the team to produce photovoltaic devices with high yield and large areas and efficiently create electricity from sunlight. These peroxide solar cells also have a long working life. Through a simple impregnation method, the team was able to deposit a uniform, high-quality peroxide crystal film covering a large effective area in two minimodules, one of which was about 16 square centimeters and the other nearly 37 square centimeters. Manufacturing a uniform thin film over the entire photovoltaic module area is critical to the performance of devices.

The power conversion efficiency of the mini-modules that the researchers took out reached 17.58% and 16.06%, which is the highest level reported currently. Power conversion efficiency is a measure of the efficiency of converting sunlight into electrical energy. For other peroxide manufacturing methods, one of the main obstacles to industrial scale manufacturing is its narrow processing window, that is, the time during which the film can be laid on the substrate. In order to obtain a uniform crystalline film, and to combine well with the underlying layer, the deposition process must be strictly controlled within a few seconds.

The use of sulfane in the peroxide's precursor can extend the processing window from 9 seconds to 90 seconds, forming a highly crystalline compact layer on a large area; at the same time, we are less dependent on processing conditions. The sulfane method can be easily adapted to existing industrial manufacturing technology, which helps pave the way for commercialization.

Peroxide is any material with a special crystal structure similar to mineral peroxide. Peroxides can be designed and manufactured for extremely thin films, which makes them very useful in solar photovoltaic cells.