Zong and others used hydrophobic carbon ink as the counter electrode to prepare PSCs without a hole transport layer at relative humidity of 45%. Perovskite materials will degrade when being in contact with moisture in the forming process. In previous studies, inert gas atmosphere or controlled vacuum was usually used to reduce the degradation of perovskite. Adding NHCI to the perovskite precursor solution allows the perovskite to form large-sized grains under relative humidity of 45%, which increases the connectivity between the crystals, and makes the perovskite layer and carbon electrode layer be in close contact. Adding a proper amount of NHCI makes the battery prepared under high humidity conditions obtain efficiency of 9.89%, and the battery's efficiency is not significantly reduced when it is stored in the air for a long time. Yang and others also added NH4Cl as an additive to the CH3NH3I solution, and then formed a smooth perovskite light-absorbing film; prepared FTO/ZnO/CH3NH3PbI3/C plate structure of PSCs without hole transport layer. Low-temperature carbon ink electrodes is deposited by using the scraper in the air. The perovskite layer and carbon electrode layer are in uniform and close contact, so that the battery has good environmental stability. Wang and the rest of the team mixed Cs with MAPbI3, and used carbon ink as the counter electrode, which greatly improved the hydrophobicity of the cell and improved the stability of the device. The cell's efficiency reached 10.57%.

2. The application of graphene to the counter electrode layer

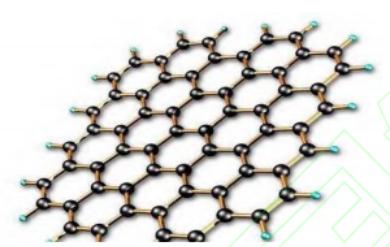

Figure 1 The structure of the graphene

Graphene which is known as the king of the new material has a honeycomb two-dimensional structure as shown in Figure 4 and consists of only one layer of carbon atoms. It is currently the material with thinnest and smallest resistivity, which has a large specific surface area, good bending, high optical transmittivity, high carrier mobility and many other advantages. Graphene is usually used as a photoanode due to its good transparency. In recent years, researchers have found that when it was used as a counter electrode, it also has excellent performance; it is one of the few carbon materials that can be used as both a photoanode and a counter electrode. For example, Yan and others directly deposited flexible graphite on CH3NH3Pbl3 and controlled the Fermi level by controlling the number of graphene layers. Compared with single-layer graphene, multilayer graphite is more compatible with CH3NH3Pbl3, which not only accelerates the extraction rate of holes, and plays a role in blocking electrons, thereby obtaining high photoelectric conversion efficiency of 11.5%. Subsequently, Wei and others synthetized a new type of graphene with a three-dimensional honeycomb structure. The resistance value of graphene could be adjusted by controlling the synthesis time. When the reaction time is 48 hours, the graphene's resistance is the smallest. The conductivity is the highest, and the performance of the hole transport is the best. Graphene used as the counter electrode in the hole transport layer PSCs has efficiency of 10.06%.

Because the preparation method of graphene is cumbersome and does not match the energy level of perovskite materials, the research on graphene used in perovskite solar cells is rare. However, graphene has excellent optical and electrical properties. If its preparation technology is improved, its Fermi energy level is adjusted to match the energy level of perovskite materials, or it is compounded with other materials, the great potential of graphene being applied to perovskite solar cells is likely to be stimulated.

3. The application of other carbon materials to the counter electrode layer

The research on the above carbon materials alone cannot meet the requirements for the development of perovskite solar cells, and other types of carbon materials have been gradually developed. In 2014, Wei and others used candle soot to prepare the carbon counter electrode of PSCs. Because it has a hole selective filtering property similar to biofilm, it greatly prevented the transmission of electrons, thereby increasing its conductivity, and making PSCs obtain a maximum conversion efficiency of 11.02%. In 2016, Gholipour and others prepared cheap composite carbon fiber or carbon cloth as the counter electrode of PSCs. The initial battery efficiency reached 14.8%, and the efficiency loss was extremely slow, which greatly enhanced the stability of the cell and extended the service life of the battery. In 2018, researchers used cheap activated carbon as the battery's counter electrode for the first time, and at the same time eliminated the expensive hole transport layer, which greatly saved the manufacturing cost of the battery. In the same year, Sajid and the rest of the team prepared a NiO@CSs (a carbon ball) composite material with morphology similar to rambutan as the counter electrode. The small hole of the composite makes it have close contact with the perovskite layer, which improves the collection efficiency of photo-generated holes and reduces the composite quenching. The addition of NiO makes the energy level of the carbon electrode or perovskite interface more matched, thereby minimizing the charge extraction barrier and obtaining a higher Voc.

In addition, the tightly connected structure of the composite material more effectively prevents moisture and oxygen from contacting the perovskite material, extending the service life of the cell in an environment with high humidity. By optimizing the mass ratio of nickel oxide to carbon balls, the battery finally obtained high efficiency of 11.70%. Later, Mali and others made the gel in the aloe into powder, washed the powder with hydrochloric acid, and processed it at a high temperature of 1000℃ to obtain nanoparticles. The cell's efficiency reached 12.58% by using the obtained nanoparticles as the counter electrode of the battery. The initial efficiency of 85% was still maintained after 1000 hours. In 2019, Meng and others used the hot pressing method to carbonize powder coal at 1050℃ and used it as a counter electrode material. Compared with other common counter electrode materials, powder coal has a wide range of sources and extremely low prices. Under the optimal experimental conditions, the efficiency of PSCs based on carbonized powder coal electrodes reached 10.87% (0.3cm2), which provides a new way for large-scale industrial applications of PSCs.

In 2020, in order to reduce the cost of the counter electrode, researchers used bamboo chopsticks (BC-B), peanut shells (PS-B), reeds (PA-B) and corn stalks (CS-B) to make biomass carbon counter electrodes and make a comparison. It is found that the biomass carbon materials all had an amorphous structure, and TEM did not show an obvious crystal lattice. The order of crystallinity was BC-B, PS-B, PA-B and CS-B. Among them, BC-B has the highest degree of graphitization, and good interface contact with the perovskite layer was observed, with the highest efficiency of 12.82%. Later, Pitchaiya and others extracted porous graphitized carbon from an invasive plant (Eichhornia Crassispes) and used it as a counter electrode for PSCs. The graphitized carbon extracted at different annealing temperatures of 450℃, 850℃ and 1000℃ was compared. At an annealing temperature of 1000℃, the graphitization is the best, and the conductivity is the best. The highest efficiency is 8.52%, and the cost is greatly reduced. With the continuous efforts of scientific researchers, the sources of carbon materials are wider; the price is lower, and the effect is better, which will make a great contribution to the large-scale application of PSCs.