2. The research and development progress of the solar cell

At present, although the research on second-generation thin-film solar cells and third-generation new solar cells has made great progress, many of them are still in the laboratory research and development stage. In 2017, the market share of crystalline silicon solar cells was as high as 95% in terms of shipments of solar cells in the world.

2.1 Research and development progress of high-efficiency silicon-based solar cells

The improvement of efficiency of solar cells mainly depends on the improvement of cell structure, materials and fabrication processes. Generally, solar cells with the conversion efficiency of monocrystalline silicon greater than 18%, polycrystalline silicon 16.5%, and amorphous silicon film 10% are called high-efficiency cells. It's very limited to improve the cell's conversion efficiency through the optimization of traditional manufacturing processes, and further improvement of cell efficiency requires the development of new cell structures and manufacturing processes. At present, the new-type solar cells with good industrialization and development prospects mainly include back point-contact cells (PCC), passivation emitter (PE) cells, such as Passivation Emitter of Solar Cells (PESC), Passivated Emitter and Rear point Contact (PERC), Passivated Emitter and Rear Locally-diffused (PERL), Metallization Wrap-Through (MWT) cells, etc. Domestic and foreign solar cell manufacturers have made great progress in the development and industrialization of high-efficiency silicon cells.

2.1.1 "Pluto" solar cells

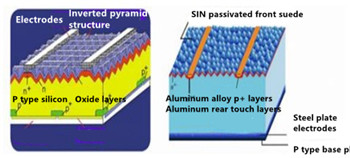

Suntech Solar Power Co., Ltd.'s "Pluto" solar cell (Figure 1) is a P-type high-efficiency crystalline silicon solar cell based on the PERL technology route and using advanced semiconductor processes. The conversion efficiency of mass-produced monocrystalline silicon solar cells is 18.8%, and that of polycrystalline silicon solar cells is 17.2%.

Figure 1 The schematic diagram of the structure of pluto solar cells

2.1.2 SE solar cells

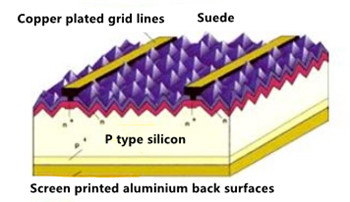

The Selective Emitter (SE) solar cell of CLP Electric Photovoltaic Co., Ltd. (Figure 2) is based on PERL technology and selects the part that improves the cell efficiency most obviously and is easier to industrialize. The average conversion efficiency of the cell is 17.6%, and the highest is 18.5%.

Figure 2 The schematic diagram of the structure of the SE solar cell

2.1.3 HIT solar cells

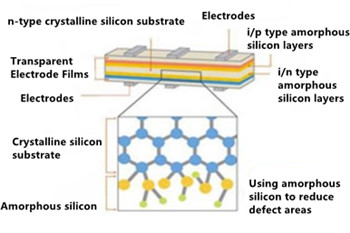

The HIT solar cell of Japan's Sanyo Electric Co., Ltd. achieved mass production in 1997 and registered "HIT" as a trademark. In 2009, Panasonic Corporation acquired Sanyo Corporation. By improving the amorphous silicon's formation process, the laboratory efficiency of the HIT cell (Figure 3) using the back contact structure reached 25.6% in 2014, and the conversion efficiency of the HIT module reached 23.8% in 2016.

Figure 3 The schematic diagram of the HIT solar cell's structure

2.1.4 Panda Solar Cells

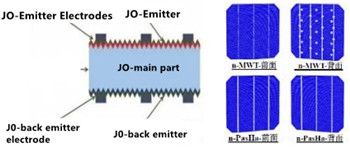

Yingli Group's "Panda" high-efficiency monocrystalline silicon solar cell (Figure 4) is an N-MWT solar cell technology developed from the integration of N-type bifacial cells and MWT technology. At present, the average efficiency has reached 19%. The highest efficiency is 20%. The initial light attenuation of PANDA cell device is lower than that of ordinary P-type monocrystalline silicon, and the temperature coefficient is 6% to 9% lower than that of P-type monocrystalline silicon, which is better than the weak light of P-type monocrystalline silicon cells. Double-sided power generation can be obtained by adopting a transparent backplane.

Figure 4 The schematic diagram of the structure of the Panda solar cell

2.2 Progress in conversion efficiency of the solar cell

The percentage of the maximum output electric power of the solar cell to the absorbed light power when the external circuit is connected is defined as the photoelectric conversion efficiency, referred to as the conversion efficiency. The maximum theoretical conversion efficiency generally takes the maximum thermodynamic efficiency as the S-Q (Shockley-Queisser limit) efficiency limit. In actual solar cells, the conversion efficiency can only approach the theoretical value due to the reflection of the panel and the thickness of the photoactive active layer, non-radiative recombination and resistance. Table 1 lists the theoretical and current best experimental efficiencies of the main types of solar cells, and briefly summarizes the characteristics of different types of cells.

Table 1 Experimental efficiencies and characteristics of different types of solar cells

| Types | Theoretical efficiency (%) | Highest experimental efficiency (%) | Advantages |

Disadvantages |

| Monocrystalline silicon | 30 | 25.6 | High efficiency and long service life |

The cost is high, and it is difficult to further improve the efficiency. |

| Polysilicon | 30 | 21.3 | Low costs and simple preparation | Efficiency still needs to be improved and there is room for improvement |

| Amorphous silicon | 30 | 19.4 | Low costs and simple preparation | The efficiency is low and it is not stable. |

| CdTe | 28 | 21.5 | Low costs and simple preparation | It contains the poisonous rare element Cd. |

| CIGs | 29 | 22.3 | Low costs, good stability, good anti-radiation ability | It contains rare elements In and Se. |

| Single crystal GaAs | 30 | 27.5 |

High efficiency and good radiation resistance | It has high costs, complex production and long period. |

| Thin-film GaAs |

30 | 28.8 | High efficiency and good radiation resistance | It has high costs, complex production and long period. |

| InP | 29 | 22.6 | The best anti-radiation ability and good stability | The cost is excessive cost and the raw material is rare. |

| CZTS | 32.2 | 12.6 | Low costs and cheap raw materials | It has low efficiency. |

| Organic polymer solar cells | 32.2 | 12.6 | Low costs and cheap raw materials | Low efficiency |

| Dye-sensitized solar cells | - | 14.7 | Low costs and simple processes | Low efficiency |

| Quantum dot solar cells | 44 | 14.98 | They can expand the absorption spectrum and have good stability. | Low efficiency |

| Perovskite solar cells | 31 | 23.7 | The cost is very low; the process is simple, and the efficiency is high. | It contains the toxic element Pb and has poor stability. |