Research on heat dissipation of low multiple concentrating photovoltaic systems

Since the surface temperature of the cell in the low multiple concentrating system is not very high, taking into account costs, passive heat dissipation is often used. Generally, heat dissipation is considered when the concentration ratio is greater than 2. A copper or aluminum heat dissipation base plate can be installed on the back of the cell, or a finned radiator can be installed. The natural convection of air can be used to meet the requirement for cooling.

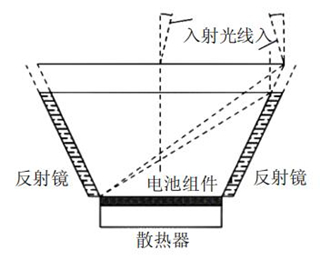

Ke Cheng and others established a low multiple concentrating photovoltaic system with a single parabolic reflector. The temperature rise measured by the experiment was only 1.0 to 2.0C, and cooling measures were not required. However, this type of concentrator would cause uneven distribution of the spectral irradiance on the surface of the solar cell, and cause partial damage in severe cases. Therefore, ordinary polysilicon photovoltaic modules could be used. Jinping Wang has designed a double V-groove low multiple concentrating photovoltaic system. As shown in Figure 1, a simple heat sink was installed on the back of the cell for passive cooling. The cell power was increased by 27%, and the surface temperature was controlled at 44.8℃. However, the stability of the device still remains considered.

Figure 1 Double V-groove low multiple concentrator systems

Research on heat dissipation of medium multiple concentrating photovoltaic systems

Generally, flat panel radiators with fins are used under medium multiple conditions, and there are also examples of installing heat pipes to dissipate heat. A heat pipe is a device that uses a heat storage two-phase flow medium to transport heat from one end to the other. It is composed of evaporation sections, adiabatic sections and condensation sections. The evaporation section of the heat pipe is partially attached to the back of the photovoltaic cell to absorb the heat. The working medium in the heat pipe evaporates and flows to the condensing part; releases its latent heat to the surrounding environment through natural convection. In addition, some novel and high-efficiency heat dissipation methods are gradually being applied to medium multiple concentrating photovoltaic cells, such as the liquid immersion cooling technology and falling film evaporation technology. The former is to immerse the solar cell in an insulating cooling medium, and the heat is directly transferred from the upper and lower sides of the cell. However, the encapsulation of the solar cell and the light transmittance of the cooling medium also need to be considered. The latter is that the liquid flows downward from the wall of the solar cell in the form of a thin liquid film under the action of gravity. In this process, the thin liquid film transfers heat between the wall and the air. As part of the liquid evaporates, the latent heat of vaporization taken away by the liquid will greatly increase the heat and mass transfer efficiency. Domestic scholars have done a lot of research on the heat dissipation and cooling of solar cells under medium multiple conditions, and the results are shown in Table 2.

Table 2 Research results of heat dissipation methods under medium multiple concentrating conditions

| Researchers | Concentrating multiples | Cooling methods | Research results |

| Haijun Xiang | 16 X | Cooling of the liquid immersion | When the normal direct irradiance (DNI) of the sun is 910 W/m2, the inlet temperature of the fluid is 8.2℃, and the flow rate is 0.544 L/s. The maximum temperature of the cell module does not exceed 16.5℃, and the unevenness of the temperature does not exceed 3℃. When the inlet flow rate of the fluid is 1.08 L/s, the convective heat transfer coefficient between the cell component and fluid can reach 750 W/(m2. K). |

| Zilong Wang | 50 X | Cooling of heat pipes | When the filling rate is 30% and the ambient temperature is 302K, the cell temperature is 330.84 K; the bottom surface temperature of the evaporation end is 354.69K. As the concentration ratio increases, contact thermal resistance is one of the main factors affecting photovoltaic cells. |

| Xusheng Shi | 99 X | Cooling of falling films | When the inlet temperature of the liquid is 30°C and the flow rate is 300 L/h, the simulated solar cell temperature can be controlled below 60°C; the temperature difference between the horizontal and vertical distribution is less than 5°C and 10°C. |

Research on heat dissipation of high multiple concentrating photovoltaic systems

The high photoelectric conversion rate and area utilization rate make high multiple concentrating solar cells a hot topic. When designing a cooling system, you should consider low and uniform cell temperatures, reliability of systems, sufficient capacity and minimum power consumption. If the cooling system is not used, the temperature of the cell surface will be higher than 150°C due to the high multiple concentrating. High multiple concentrating is often used in conjunction with dense modular cells, so the heat dissipation method is the same as what was described above, mainly considering some heat exchange methods such as the micro-channel heat sink, jet impact, and two-phase flow. Many scholars have conducted a series of theoretical analyses and experimental research and have achieved a lot of results as shown in Table 3.

Table 3 Research results of heat dissipation methods under high multiple concentrating conditions

| Researchers | Concentrating multiples | Cooling methods | Research results |

| Royne | 500 X | Jet impact | The heat transfer coefficient is estimated to be 3.7X 10' W/(m2. K), and a variety of different jet holes have been verified through experiments, among which the sharp-edged jet hole has the least power consumption. |

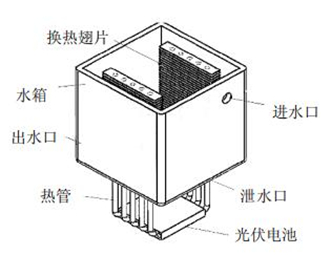

| Haifei Chen and others | 319 to 1274 X | Cooling of heat pipes | As shown in Figure 8, the heat pipe replaces the fin type air-cooled photovoltaic radiator and the pipeline-type water-cooled photovoltaic radiator, which can not only cool evenly, but also collect heat. The theoretical calculation shows that the surface temperature of the cell can be maintained between 40 to 70°C, realizing the comprehensive photoelectric and photothermal utilization. |

| Xusheng Shi | 590 X | Cooling of falling films | When the inlet temperature of the liquid is 30°C and the flow rate is 300 L/h, the simulated solar cell temperature can be controlled below 90°C. |

| JuX and others | 953 X | Manifold micro channels | The total thermal resistance of the system is lower than 10-4 (m2.K)/W at a flow rate of 100 to 400 mL/min for the cooling medium, achieving cooling of high heat flux at a low cost. |

Figure 4 Heat pipe cooling collectors

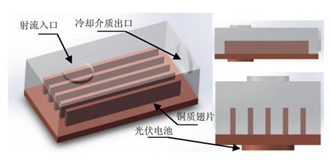

A water-cooled heat exchanger with fins is designed in this article, as shown in Figure 9. Under the conditions of a concentrating multiple of 400X and a limiting temperature of 50°C of the cooling medium, the cell surface temperature was controlled at 59.73°C combined with jet impact technology, which met the requirements for photovoltaic cells working below 60°C. The heat exchanger was tested and numerically simulated and the results showed that the highest surface heat transfer coefficient of the heat exchanger was 9688W/(m2.K). The average surface heat transfer coefficient was 5075 W/(m2.K). A mass flow rate of 0.1 kg/s was determined as the optimal operating flow rate through studying the relationship between the flow rate and heat transfer of jet flow heat exchangers.

Figure 5 Jet water-cooled heat exchanger with fins

3. Conclusion

In recent years, as the price of international traditional fossil energy has risen and environmental problems have become increasingly prominent, renewable energy sources such as solar energy have become the attention all over the world. The utilization of solar photovoltaic and photothermal has also become a hot topic for researchers. The development of relevant markets and mature and efficient technologies are of great significance to the energy security of China and the world.