The application of graphite or carbon black in the counter electrode layer

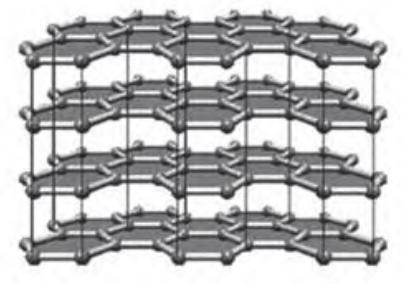

Figure 1 The structure of graphite

The lamellar structure shown in Figure 1 is graphite. Each carbon atom in the layer is connected to the other three carbon atoms through covalent bonds. Each carbon atom can release an electron that can move freely, which makes graphite have good conductivity and be used as the counter electrode material of perovskite solar cells. Its specific surface area is small and its adhesion is poor, so it is usually not suitable as a counter electrode alone. Adding carbon black that has a large specific surface area can optimize the connection between graphite to better contact the perovskite layer. The combination of the two materials can have a very good performance, which can't be obtained by single material alone. A pair of electrodes is made for PSCs by conductive carbon black and graphite in a ratio of 1:3 in 2013. The photoelectric conversion efficiency reached 6.64%. Its good performance set a precedent for carbon to replace precious metal like Au or Ag counter electrodes, and greatly reduced the overall cost of PSCs.

Since then, researchers have begun a large number of studies on the performance of cells of this composite carbon as a counter electrode. In 2014 and 2017, through optimization experiments, the cell efficiency of this composite carbon as a counter electrode is increased to 12.84% and 14.02% respectively, and the stability was good, laying the foundation for the large-area manufacturing of carbon counter electrodes. In 2014, the conductivity of the original commercial carbon paste counter electrode is increased by pressing the graphite film tightly on the counter electrode made of commercial carbon paste, and dried it at room temperature, so that the photoelectric conversion efficiency of the cell reached 10.2%. Graphite or carbon black is used to make a smooth and dense carbon film, and the effects of different sizes of graphite on the conductivity of the carbon film and the ability to penetrate the perovskite precursor are studied. This carbon film has very good contact with the perovskite layer, providing a fast channel for hole extraction. The efficiency of hole transport is improved, and the device efficiency reaches 11.63%.

In 2017, ink made of carbon black, CH3NH3I and organic solvent is adopted. The carbon counter electrode is deposited directly on the PbI2 film by spraying, and the efficiency of the device reaches 11.6%. The mechanical exfoliation method is used to prepare ultra-thin graphite, and the ultra-thin graphite treated by this method has a fine and uniform surface. On the condition that the conductivity of the graphite is not sacrificed, the specific surface area of the carbon layer is effectively increased, and the contact with the perovskite layer is increased. The efficiency of the cell is increased from 12.63% to 14.07%. The mismatch of energy levels of carbon and perovskite is a major factor limiting the efficiency of carbon-based perovskite solar cells without a hole transport layer. Use graphite or carbon black as the counter electrode and fine-tune the oxygen content in the carbon black. The oxygen content in the carbon counter electrode will affect the energy level arrangement and interface contact between the perovskite layer and the counter electrode layer. Oxygen-containing carbon can easily interact with lead through lead-oxygen coordination. At the same time, high oxygen content usually makes the carbon produce a big interplanar space, increasing the contact between the specific surface area of carbon and the perovskite layer, significantly improving the hole extraction efficiency at the interface between the perovskite and counter electrode, and the optimal efficiency of the cell reaches 15.7%.

With the in-depth study of carbon on the electrode, it is found that the carbon material can be mixed to improve the poor hole extraction ability of the carbon electrode of the hole-transport layer perovskite solar cell. The CuS nanostructure of Р type semiconductor is mixed with carbon paste, and the electrode is prepared by the knife coating under low-temperature conditions. When the optimal amount of 1wt% CuS is added, the open-circuit voltage (Voc) is as high as 0.98V, making the highest efficiency to be 11.28%. Later, the researchers added WO3 nanoparticles to graphite powder to prepare carbon paste through a series of chemical methods. When 7.5% of WO3 (calculated by volume) was added, the cell obtained 10.5% of the maximum photoelectric conversion efficiency. Copper phthalocyanine (CuPc) with graphite or carbon black to prepare counter electrode slurry. CuPc was used as a dopant and perovskite or carbon surface modifier at the same time to make the holes more effectively transfer from the perovskite layer to the carbon electrode layer. The best efficiency of 14.8% is obtained when there is 1.0wt% of CuPc, which is 30% higher than the pure carbon electrode.

At the same time, they deposited CuPC on the thin film between the perovskite and carbon electrode. The device's efficiency is low and the hysteresis is also obvious due to the poor conductivity of CuPC itself. Compared with the CuPc intermediate layer between the perovskite or carbon, the CuPc modified carbon electrode device shows better performance. In addition, the CuPc modified carbon electrode was applied to a 5 cm x 5 cm large-area rigid substrate or flexible substrate to prepare solar cell modules, and excellent results were obtained. Graphite or carbon black particles and perovskite crystals are both rigid structures, so there is a big gap in the interface contact between the perovskite layer and the carbon electrode layer. Use a water assisted annealing method, that is, after the complete device is prepared, it is placed in an environment with suitable humidity for annealing, so that the perovskite will further crystallize. It not only improves the crystalline quality of the perovskite film, but also makes the contact between the perovskite film and the carbon electrode more compact. When the humidity is 30 RH, the cell obtains an efficiency of 12.82%. The dense carbon film protects the perovskite film, which makes the efficiency loss of perovskite is small in the air for a long time.

In order to study the effect of annealing temperature on the electricity, morphology and structural properties of the carbon film, the researchers used different temperatures to anneal the fully printed substrate composed of FTO/c-TiO2/m-TiO2/m-ZrO2/C before the perovskite is permeated. The carbon film with 20 um is composed of graphite particles, carbon black nanoparticles, terpineol, organic binder, and an inorganic binder. The higher the temperature is, the more complete the volatilization of organic solvents and binders becomes. The conductivity of the carbon film increases with the annealing temperature. carbon particles will contact more and the orderliness of the structure will be better at high temperatures, which is conducive to carrier transport. When the annealing temperature is 400℃, the cell achieves the best efficiency of 13.3%, indicating that a high temperature of over 300℃ for annealing is very necessary before infiltration of the perovskite.

The above research shows that the structural integrity of the carbon electrode is easily destroyed due to the poor bonding force of pure carbon black, resulting in poor electrode conductivity. However, flake graphite is difficult to form good contact with the perovskite due to its large size, resulting in a decrease in the performance of the cell. However, mixing graphite with good conductivity and carbon black with a large specific surface area can be used as an excellent counter electrode material, which not only obtains better efficiency of cells, but also improves the stability of cells. The appearance of graphite or carbon black composite counter electrode has attracted widespread attention from scholars and has a certain role in promoting the development of carbon-based perovskite solar cells.